Omnichannel inventory management: what it is and best practices

With global online sales expected to surpass $7 trillion by 2025, businesses need to adapt — or risk falling behind. Modern consumers aren’t just looking for products; they’re after smooth, fast, and reliable experiences across all touchpoints.

Meeting these evolving expectations means mastering solid omnichannel inventory management — and placing it at the heart of your ecommerce operations. But what exactly does this involve? And how can you maintain omnichannel selling as you scale?

This article unpacks the essentials of omnichannel inventory management, explains why it’s critical for your success, and outlines how to optimize your approach for maximum efficiency.

Inventory management savings calculator

What is the current cost of your mis-ships, out of stocks and lack of labor efficiency?

What is omnichannel inventory management?

Omnichannel inventory management keeps your stock flowing smoothly across every sales channel — from your online store to marketplaces to brick-and-mortar stores. It’s about visibility, control and delivering seamless customer experiences — no matter where or how your shoppers browse and buy.

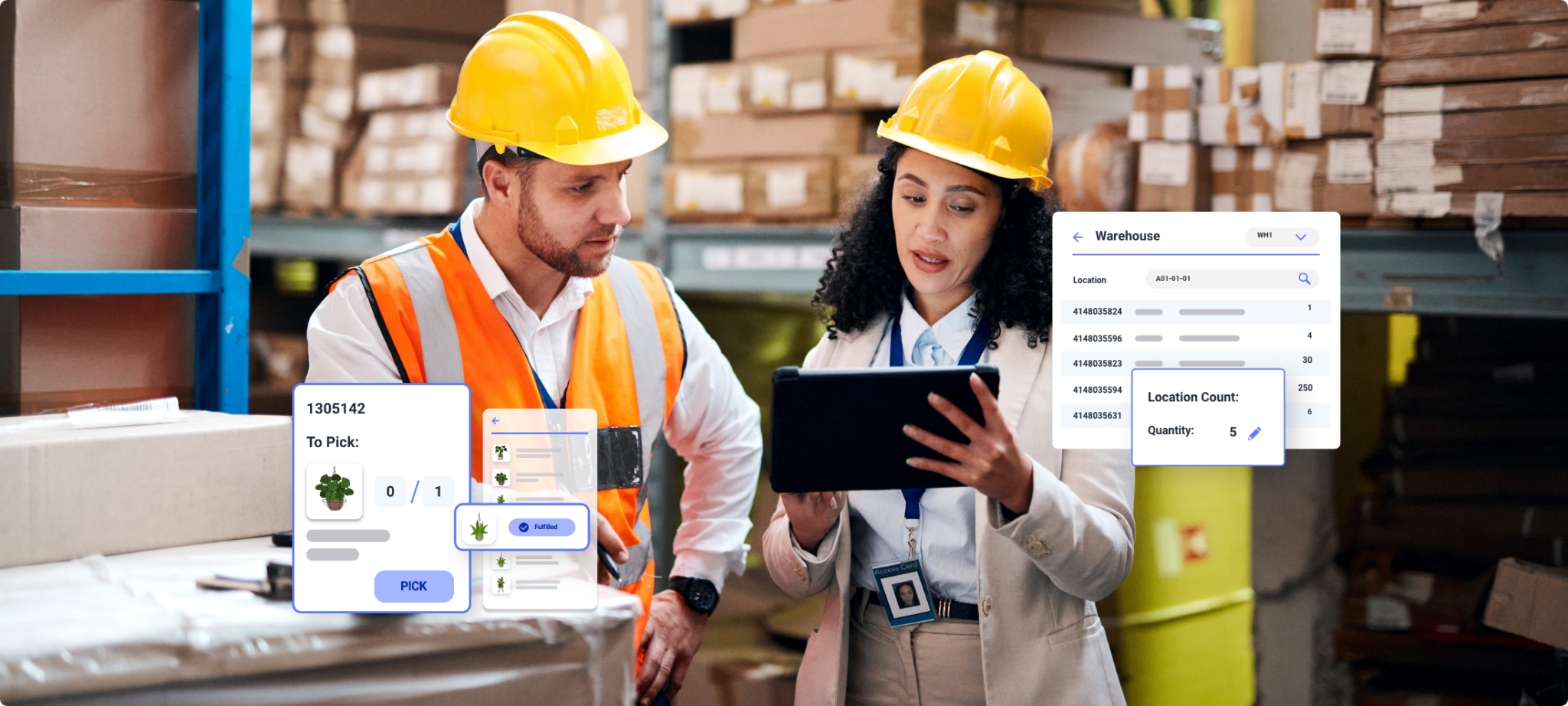

Good omnichannel inventory management software allows you to track and manage inventory across all sales channels from a central location.

This means retailers have real-time visibility into their inventory levels, whether a product is sold in-store, online, or through a third-party marketplace. Moreover, effective omnichannel order management ensures that orders are accurately fulfilled and delivered, enhancing the overall customer experience.

Master your marketplace strategy: A guide to success

Expand into international marketplaces with confidence. This guide helps you choose the right strategy to scale successfully and reach global customers.

Who’s Winning with Omnichannel Inventory Management?

Industry leaders like Amazon, Starbucks, Target, and Best Buy have mastered omnichannel inventory management—and their success proves its value.

- Amazon sets the standard with real-time stock visibility and lightning-fast fulfillment.

- Starbucks seamlessly integrates mobile and in-store ordering for a frictionless customer experience.

- Target & Best Buy leverage buy online, pick up in-store (BOPIS) and hassle-free returns to drive convenience and loyalty.

The impact? Businesses with strong omnichannel strategies retain 89% of customers, compared to just 33% for those without (Aberdeen Group). Harvard Business Review also found omnichannel shoppers spend 4% more in-store and 10% more online than single-channel customers.

With benefits like reduced stockouts, higher fill rates, and increased profitability, omnichannel inventory management is no longer optional—it’s a competitive necessity.

The Power of Omnichannel Inventory Management

Why It Matters

Inventory inconsistencies can break the customer experience. Imagine a shopper finds a product online, visits your store to buy it—only to discover it’s out of stock. These frustrating moments can cost you customers and damage brand loyalty. That’s why omnichannel inventory management isn’t just an advantage—it’s essential for long-term success.

Key Benefits of Omnichannel Inventory Management

✅ Prevent Stockouts & Overselling – Keep inventory updated in real time across all channels, ensuring customers always find what they need.

✅ Enhance Customer Experience – Deliver seamless shopping—whether customers browse online, buy in-store, or return via another channel—driving loyalty and repeat purchases.

✅ Lower Operational Costs – Automate inventory tracking and fulfillment to reduce manual work, minimize errors, and increase efficiency.

✅ Maximize Sales & Profits – Improve stock availability, optimize order fulfillment, and capture more revenue opportunities.

Why You Need a Centralized Inventory Solution

Managing inventory manually—through spreadsheets or disconnected channel dashboards—leads to:

- Inconsistent stock tracking, increasing risk of errors.

- Missed sales opportunities due to overselling or lack of real-time updates.

- High operational costs from inefficient manual processes.

The solution? A single source of truth for all inventory data—empowering retailers to manage stock seamlessly across every channel and deliver a frictionless shopping experience.

Differences between omnichannel and multichannel retailing

Omnichannel retail and multichannel retailing are both terms used to describe the practice of selling through multiple channels. Multichannel retailing manages each channel separately, which often creates disjointed customer experiences. The key difference between the two is that Omnichannel retailing unifies all channels into a single strategy for managing inventory ensuring a cohesive experience at every touchpoint. omnichannel retailers have a unified strategy for managing inventory across all channels, while multichannel retailers manage each channel separately.

Say you’re currently using a multichannel way of selling your goods, including your online store, brick-and-mortar store, social media sales, etc. So, what’s the difference between doing that and switching to an omnichannel approach?

The primary thing that makes omnichannel better for you and your consumers is that each step is connected. In fact, integrating everything will make it much easier for customers to get what they want.

Also, using the omnichannel retailing approach can save you a lot of money because you’ll use a much more unified inventory system.

Even better, your customers will appreciate being able to buy something online yet return it to your store. But, of course, there are multiple obstacles and challenges you must overcome first.

Multichannel retailing manages each channel separately, which often creates disjointed customer experiences. Omnichannel retailing, on the other hand, unifies all channels into a single strategy ensuring a cohesive experience at every touchpoint.

Think of it like the conductor of an orchestra ensuring every instrument (or sales channel) plays in perfect harmony. With omnichannel inventory management, your business can maintain real-time stock updates, avoid the dreaded “out of stock” notification and ensure happy customers everywhere. It’s not just about managing inventory; it’s about mastering the art of balance in a busy, connected commerce world.

How does an omnichannel strategy improve efficiency in ecommerce operations?

Omnichannel inventory management is like your business’s secret weapon for cutting through the noise. By centralizing your operations, it transforms the complex web of multi-channel selling into a smooth, synchronized system.

With real-time inventory tracking, you know exactly where your products are and how many you have — whether they’re on warehouse shelves, in transit or on their way to customers. Automation steps in to handle repetitive tasks like stock updates and order fulfillment, giving your team more time to focus on growing the business. And when all your channels are working together, errors like overselling or stockouts become a thing of the past.

An omnichannel strategy doesn’t just keep things moving — it turns your operations into a well-oiled machine primed for growth and customer satisfaction. Research from Accenture indicates that 73% of consumers prefer shopping across multiple channels, making omnichannel efficiency a key driver of long-term loyalty and sales growth.

The sustainability advantage of omnichannel inventory management

Omnichannel inventory management is not only about operational efficiency and customer satisfaction — it also has significant sustainability benefits. By optimizing inventory processes, businesses can reduce waste, minimize carbon footprints, and contribute to a more sustainable future.

- Reduced waste: With better inventory visibility, businesses can avoid overstocking and minimize unsold goods that might otherwise end up in landfills. Predictive analytics and demand forecasting ensure that stock levels align with actual customer demand, reducing excess.

- Optimized transportation: Centralized inventory systems enable more efficient logistics, cutting down on unnecessary transportation. Fewer shipments mean lower emissions, aligning with eco-friendly practices.

- Energy-efficient operations: Automation and streamlined processes reduce the need for energy-intensive manual work. Warehouses and fulfillment centers can operate more efficiently, conserving resources.

- Improved product lifecycle management: By understanding customer demand patterns and managing returns effectively, businesses can extend the lifecycle of products. Items can be redirected to different channels or refurbished for resale, reducing waste.

Sustainability is increasingly important to modern consumers. A survey by Nielsen found that 73% of global consumers say they would change their consumption habits to reduce environmental impact. By integrating sustainability into omnichannel inventory management, businesses can appeal to eco-conscious customers while also cutting costs and improving efficiency.

Omnichannel inventory management challenges

What stands in the way of getting your company’s omnichannel order management system up and running? Consider the following.

Tech limitations

Outdated systems or incompatible tools can disrupt efficiency. Many businesses still rely on spreadsheets or legacy software that lack real-time capabilities, making it nearly impossible to keep pace with modern ecommerce demands. Additionally, integrating newer systems into an existing infrastructure can be costly and require a steep learning curve for teams.

Disconnected supply chain processes

In order for an omnichannel inventory system to work, every link in your supply chain must be connected. This includes your vendors, manufacturers, logistics providers, and more.

If any of these parties aren’t using compatible software or don’t have a way to communicate with each other, it will throw a wrench in your inventory management system. The good news is that there are plenty of software solutions available that offer built-in supply chain management features.

SkuVault Core, for example, includes a vendor management system (VMS) that gives you the ability to track and manage your relationships with vendors all in one place.

Order inaccuracy

With so many moving parts, it’s important to have a system in place that can keep track of everything and ensure accuracy.

An inventory management solution will give you the ability to see your inventory levels in real-time across all channels, so you can make adjustments as needed.

It will also automate tasks like order fulfillment and shipping to help reduce errors. Omnichannel inventory management is a complex process, but it’s one that can have a major impact on your business.

By taking the time to implement a system, you can improve customer satisfaction, reduce operating costs, and increase revenue and margins.

Lack of inventory visibility

If you can’t see your inventory levels in real-time, it’s impossible to manage them effectively. This is one of the biggest challenges businesses face when trying to implement an omnichannel inventory management system.

Without visibility into your inventory, you run the risk of overselling products, which can lead to angry customers and lost sales.

Data Silos

Data silos are a major headache, making it hard to get a unified view of your inventory. When systems don’t communicate, each platform essentially becomes an isolated island. This disconnect often leads to overstocking on some channels while running out of stock on others, resulting in lost sales and wasted resources. Breaking down these silos requires integrating your systems into a centralised platform but achieving that can be complex without the right tools.

High storage costs for inventory

It’s imperative that you have a dedicated place within your processing center for each of your sales channels.

Failure to do so invites dead stock and excess inventory, and may leave you needing to clear out old merchandise. Instead, use your storage space appropriately to ensure that you don’t stock way more or less than is required.

Tracking your orders

You need to know exactly what goes into each order, where it came from in your inventory, and where it needs to be shipped. This is the only way you can accurately keep track of your inventory levels and ensure that orders are being fulfilled correctly.

The good news is that there are plenty of software solutions available that can help you track your orders and inventory levels. Linnworks, for example, offers real-time inventory tracking across all channels, so you always know what’s in stock.

It also includes a built-in order management system (OMS) that gives you the ability to track and manage your orders all in one place.

Inconsistent customer experiences

Shoppers expect a seamless experience but without coordination, they get let down. For example, overselling due to uncoordinated inventory updates can lead to cancelled orders while delays in restocking can tarnish your reputation. Customers today are quick to share frustrations on social media, amplifying the fallout from these missteps.

Seasonal and unexpected demand spikes

Forecasting demand accurately is challenging, especially during seasonal peaks or sudden surges in popularity. Without robust predictive analytics, businesses risk underestimating or overestimating inventory needs, resulting in either lost sales or surplus stock.

Complex returns management

Handling returns across channels adds another layer of complexity. A disconnected system might fail to update stock levels promptly, causing confusion about what’s available. This lag can create further dissatisfaction for customers and disrupt your inventory planning.

The good news? These challenges aren’t insurmountable. With the right tools like Linnworks and the right processes, you can tackle them head-on and create a system that works as seamlessly as your customers expect.

Best tips and practices for omnichannel inventory management

Centralize your inventory management

Use a single system to track stock across all channels. This eliminates silos and ensures you always have a real-time view of your inventory, reducing the risk of overselling or stockouts.

Now that we’ve looked at some of the challenges you must overcome, let’s look at some of the best tips and practices of an omnichannel inventory management system.

Know your true inventory levels

Get this: 43 percent of small businesses in the U.S. don’t track their inventory (or do so with a manual system). 43 percent!

Therefore, simply knowing your true inventory levels puts you ahead of nearly half of the country’s small ecommerce businesses.

Effective inventory management starts with having visibility into your inventory across all channels, including brick-and-mortar stores, ecommerce sites, marketplaces, and more.

The only way to do this is by using a technology solution that offers real-time inventory tracking. SkuVault Core, for example, gives you the ability to see your inventory availability in real-time across all channels so you can make adjustments as needed.

This is critical because if you don’t have visibility into your inventory, you could end up overselling products and angering customers—not to mention losing sales.

Encourage in-store returns

Encouraging in-store returns can be very helpful to your overall profit loss. After all, bringing a customer into the store to make a return has several potential bonuses for your business.

- Your customer may find what they want in the store or even discover new items to purchase.

- Customers won’t have to waste time printing a return shipping label and going to a shipment business. They will appreciate this time saved, especially if they find what they want in-store.

- Not only will you be rewarded by their in-store shopping, but you’ll also save money on the cost of paying for a shipping label. In other words, it’s a win-win!

So, what happens if they return the item in-store without purchasing anything new? No problem!

You’ll still gain the ability to sell the item in-store without having to go through the costly process of paying someone to scan it into your warehouse and re-list it online.

Integrate your supply chain

By integrating your supply chain, you’ll be able to see every step of the journey—from when an item is ordered to when it arrives in-store or at a customer’s doorstep.

This level of visibility gives you the ability to track items, so you always know where they are and when they’re expected to arrive.

It also allows you to quickly identify any potential issues that may arise so you can take steps to mitigate them.

For example, if you see that an item is going to be delayed, you can quickly update your website or app so customers are aware of the delay and won’t be left frustrated.

Omnichannel supply chain also has the added benefit of giving you visibility into your inventory levels so you can make necessary adjustments to ensure you always have the right amount of stock on hand.

This is especially critical during peak times, such as holidays when customer demand is high and you don’t want to run out of items.

Optimize your supply chain: Build strong relationships with suppliers and use predictive analytics to plan for seasonal spikes or sudden demand shifts. This keeps your operations agile and responsive.

Automate repetitive tasks: From updating stock levels to processing orders, automation saves time and reduces errors. Let technology handle the heavy lifting while you focus on scaling your business.

Optimize your return policies

Another for omnichannel inventory management is to improve your return policies. Your return policy should be clear, concise, and easy to understand. It should also be flexible so you can offer different options depending on the product, channel, and customer.

For example, you may want to offer free returns for items purchased online but charge a restocking fee for items purchased in-store.

You should also consider offering different return options such as store credit, exchanges, or refunds. And, be sure to clearly communicate your return policy to customers, so they know what to expect.

Contending with a return does, of course, cost your business some money. But not having a solid return policy could affect you even more.

Most shoppers are willing to shop somewhere more frequently if offered an easy-to-understand return policy.

Track returns effectively: A seamless returns process can make or break customer loyalty. Ensure your system syncs returns with inventory updates in real-time, maintaining an accurate stock view.

Set clear reorder points: Avoid stockouts by setting automated alerts for low inventory levels. This proactive approach ensures your bestsellers stay in stock and keeps customers satisfied.

Build a customer satisfaction plan

Another way to set your business up for success with omnichannel inventory management is to build a customer satisfaction plan. This involves creating a system for tracking and responding to customer complaints or questions.

Building a customer satisfaction plan shows customers that you care about their experience and that you’re committed to making things right if something goes wrong.

Creating a customer satisfaction plan doesn’t have to be complicated. But, it should be tailored to your business and include the following elements:

- A system for tracking customer complaints or questions

- A plan for how you will handle returns and exchanges

- A process for responding to customer feedback

- A clear, concise, and easy-to-understand return policy

Remember: satisfying your customers is one of the most important rules of the retail business. Doing so will create return customers who will spread the word about your company.

Stock your inventory across multiple locations

In the early days of online retail, it was enough to store all your inventory in one central location. But as business picked up and warehouse management became more complex, you quickly realized that this wasn’t the most efficient way to do things—especially if you were dealing with a lot of products.

Nowadays, it’s very common for businesses to have inventory spread out across multiple locations. This method has several benefits. First, it allows you to get your products closer to your customer base, which can help with shipping times. Second, it gives you a buffer in case one of your warehouses is having issues (e.g., weather problems).

And lastly, if you’re dealing with perishable items, it’s always good to have a backup plan. For instance, if one location is out of stock, you can quickly send products from another to keep your customers happy.

With these best practices, you’ll not only streamline your operations but also create a shopping experience that keeps customers coming back.

How long will it take to implement an omnichannel inventory management solution?

The time it takes to implement an omnichannel inventory management solution will vary depending on the size and complexity of your business. However, most companies can expect to be up and running within a few months.

If you’re looking for a more immediate solution, you can do a few things to get started. First, take inventory of your current stock levels and where your products are located. This step will give you a good starting point for creating an omnichannel strategy.

For more on this topic, check out our post on taking a physical count of your inventory.

Next, start thinking about how you want your customers to interact with your business. For example, do you want them to be able to purchase online and pick up in-store? Or, do you want to offer a more seamless experience where they can buy online and have the products shipped to their door?

Once you have a good understanding of your goals, you can start looking for solutions to help you achieve them. There are —several excellent options out there, so take your time and find one that’s right for your business.

Streamline omnichannel inventory management with Linnworks

When it comes to simplifying omnichannel inventory management, Linnworks is your ultimate partner. Our platform acts as the central hub for your ecommerce operations, connecting your sales channels, warehouses and inventory data in one seamless system.

With Linnworks, you know exactly what’s in stock and where, whether it’s in a warehouse or on its way to customers. Automate away tedious tasks like stock updates, order processing and shipping rules, and leverage your data to optimize inventory levels, forecast demand and improve efficiency.

Ready to turn chaos into clarity?

Book a free demo and find out how Linnworks can help you master omnichannel inventory management with confidence and ease.