Top 15 warehouse optimization software tools (2023)

In an age where digital transformation drives success, no stone of inefficiency can remain unturned.

From customer service to backend operations, every aspect of your business must be optimized to meet the expectations of today’s tech-savvy consumer – and your warehouse operations are no exception.

Efficient, streamlined warehouses are at the heart of successful businesses, particularly in the eCommerce world.

The warehouse isn’t simply a storage space for your products; it’s a hub where several critical business processes intersect.

Whether fulfilling orders promptly, managing inventory efficiently or optimizing the storage layout, your warehouse’s effectiveness directly impacts your bottom line.

That’s why the concept of warehouse optimization has gained significant importance in recent years. But what exactly does warehouse optimization entail, and why should it matter to you?

By the time you finish reading this article, you will:

- Understand what warehouse optimization entails and why it’s crucial to enhancing your business performance.

- Recognize the pivotal role of warehouse optimization software in driving efficiency and reducing operational costs.

- Be armed with a comprehensive list of the top 15 warehouse optimization software platforms in 2023, helping you make an informed decision that suits your unique business needs.

So, let’s dive into the world of warehouse optimization.

What is warehouse optimization?

Warehouse optimization is the process of improving warehouse operations using strategic planning, innovative practices, and technology to boost efficiency, reduce costs, and enhance overall business profitability.

This process involves various elements, including but not limited to:

- Warehouse design

- Warehouse automation

- Labor management

- And inventory control

A well-optimized warehouse offers a competitive edge in today’s dynamic and competitive business world. It can help businesses:

- Streamline their supply chain

- Improve order fulfillment speed

- Enhance customer satisfaction

- And even contribute to sustainable practices by reducing waste

But how does one achieve optimal warehouse efficiency? Enter warehouse management software.

The role of software in warehouse optimization

Once upon a time, warehouse management relied heavily on manual processes – spreadsheets, clipboards, and mountains of paperwork.

These labor-intensive procedures were cumbersome and fraught with inefficiencies and inaccuracies.

It was a constant challenge to keep track of inventory levels, manage space efficiently, and ensure timely delivery while controlling labor costs and avoiding errors.

With the advent of technology, warehouse operations have undergone a drastic transformation. A comprehensive warehouse management system (WMS) can completely eliminate or reduce these problems in a matter of weeks (or days).

These advanced platforms offer automated, precise, and data-driven solutions, replacing the guesswork and human error associated with manual processes with unprecedented accuracy and efficiency.

With warehouse management systems, you can now have real-time visibility into your warehouse operations. You can track inventory levels at any given moment, know exactly where items are stored for quicker retrieval and packing, and even anticipate changes in demand to adjust your stock levels accordingly.

It’s akin to having a bird’s eye view of your warehouse operations with granular detail.

Warehouse automation, a significant feature of these software platforms, has also made a sizable impact. It has eliminated the need for repetitive manual tasks, allowing your workforce to focus on more strategic, value-adding initiatives.

This change increases overall productivity and reduces labor costs and errors affecting profits.

Furthermore, features like inventory tracking and transportation management bring about a new level of control and predictability in managing your stock (and how it gets to your customers).

Instead of playing a constant guessing game, you can have accurate, up-to-the-minute information about your inventory at your fingertips.

This level of inventory control can prevent overstocking and stockouts, reduce carrying costs, and improve customer satisfaction.

In essence, warehouse optimization software has fundamentally transformed how warehouses operate.

The ability to manage inventory proactively, anticipate changes in demand, streamline picking and packing processes, and automate various warehouse functions has made these platforms indispensable.

Key features of warehouse optimization software

Inventory management and tracking

A paramount feature of warehouse optimization software is robust inventory management and tracking capabilities. This critical functionality ensures complete visibility of inventory levels and movements across your entire supply chain, whether within a single warehouse or multiple distribution centers.

Superior management solutions automate critical processes like stock counting and reordering. This automation is no small feature — it drastically reduces the risk of manual errors resulting in costly stock discrepancies or unfulfilled orders.

With features like barcode scanning, every product is tracked from the moment it enters the warehouse until it leaves, offering a precise view of stock levels in real time.

Warehouse layout and space utilization

The efficient use of warehouse space is a core aspect of warehouse optimization.

With every square foot potentially impacting operating costs, it’s imperative to use your warehouse space wisely. Warehouse optimization software provides tools for better planning storage areas and movement paths.

These capabilities ensure that each item has an optimal location, reducing wasted space, streamlining movement times, and ultimately boosting warehouse productivity.

Automation of warehouse processes

Automation, the lifeblood of modern warehouse operations, is another key feature of warehouse optimization software.

This software can automate many tasks, covering everything from receiving goods to processing orders to shipping.

The ability to automate these processes not only significantly improves efficiency and accuracy but also frees up staff to focus on more strategic tasks that enhance customer service and drive business growth.

Reporting and analytics capabilities

Data-driven decision-making is a game-changer in warehouse optimization. Warehouse management solutions have powerful analytics capabilities that offer real-time reporting and in-depth insights.

With these features, warehouse managers can monitor key performance metrics, identify trends, spot inefficiencies, and make informed decisions that improve operational efficiency and cut costs.

Integration with other systems

For a comprehensive, holistic approach to business management, warehouse optimization software must integrate seamlessly with other systems.

Integration needs can span eCommerce platforms, ERP systems, and accounting software.

A unified system ensures the smooth flow of information across different business functions, increasing operational transparency and enabling better decision-making across the entire organization.

In the complex, fast-paced world of warehouse management, this ability to have an interconnected ecosystem is vital for maintaining a competitive edge.

Benefits of using warehouse optimization software

The transformative potential of warehouse optimization software is seen in its vast array of benefits that can revolutionize your warehouse operations.

Here’s a deeper dive into how such software can elevate your business:

Improved efficiency and productivity

The automation features built into most warehouse optimization platforms can dramatically speed up operations. Processes that once took hours can be completed in a fraction of the time, significantly boosting operational efficiency.

Simultaneously, the software can enhance your team’s productivity by minimizing the need for manual data entry and reducing the likelihood of human errors. With automation taking care of mundane tasks, your workforce can concentrate on higher-level tasks, ultimately driving better business performance.

This improved efficiency also results in quicker order fulfillment times, ensuring happier customers and stronger business relationships.

Enhanced accuracy and reduction of errors

Data accuracy is paramount in warehouse management. One incorrect data entry can lead to serious consequences, such as stock discrepancies, unfulfilled orders, and dissatisfied customers.

Warehouse optimization software reduces the chance of such costly errors by automating data entry and other critical processes.

Tools like barcode scanning and real-time inventory tracking also help you maintain accurate stock levels and movement records.

This level of precision ensures that you always know exactly what stock you have, where it is, and when it needs replenishing.

Better space utilization

Efficient use of warehouse space is a crucial aspect of warehouse optimization. With software-aided layout and space planning, you can ensure maximum usage of available space.

Warehouse optimization software allows you to model your warehouse layout, identifying the best storage spots for different products based on factors like size, weight, and frequency of access.

By optimizing the use of space, you can store more inventory, streamline pick-and-pack processes, and minimize unnecessary movement. All these benefits contribute to a more efficient, profitable warehouse.

Cost savings

Efficiency is synonymous with cost savings in the world of warehouse management. Warehouse optimization software can dramatically reduce operational costs by streamlining operations and increasing productivity.

Cost savings can be seen in various areas — from labor costs, thanks to automation, to warehousing costs, due to better space utilization.

Moreover, reducing errors means fewer costs for stock discrepancies, returns, and dissatisfied customers.

In the long run, these savings will significantly impact your bottom line.

Facilitating growth and scalability

Another critical benefit of warehouse optimization software is its scalability. As your business grows and your operational demands increase, the right software can scale with you.

Handling increased orders, stock levels, and data without a hitch is crucial to sustaining growth.

Whether adding new products, expanding to new locations, or experiencing seasonal sales peaks, a scalable warehouse optimization solution will ensure you can manage these changes effortlessly.

This adaptability makes warehouse optimization software a tool for today’s operations and a strategic asset for your future growth.

Considerations when selecting warehouse optimization software

Choosing the right warehouse optimization software is a critical decision that can significantly impact your business. Here are a few considerations:

- Budget: Consider both the upfront costs and long-term ROI.

- User-friendliness: A complex, hard-to-understand system can hamper operations instead of improving them.

- Customizability: Each business has unique needs. The chosen software should be flexible enough to cater to these specific requirements.

- Scalability: The software should be able to grow with your business and handle increased loads as your operations expand.

- Quality of Customer Support: Robust, responsive customer support is crucial to address any issues that might arise during usage.

Let’s now explore the top best warehouse management software platforms of 2023.

Our top 15 warehouse optimization software picks

This selection of software solutions was carefully curated considering their functionality, user feedback, and industry reputation.

SkuVault Core

SkuVault Core is the choice for ecommerce retailers and warehouse managers who aim to eliminate human errors, enhance operational efficiency, and drive profitability.

It offers a suite of features including:

Real-time inventory synchronization

SkuVault Core synchronizes your inventory across multiple channels in real-time, ensuring you always have an accurate view of stock levels, thus preventing overselling and underselling situations.

Quality control

SkuVault Core’s robust quality control features allow you to conduct comprehensive checks to ensure that all products meet your quality standards before they reach your customers.

Warehouse reporting

SkuVault Core provides detailed reports on sales, operations, and more, allowing you to gain valuable insights and make informed decisions to optimize your warehouse operations.

To learn more, visit our features page, or take a 3-minute self-guided interactive tour of the platform.

Fishbowl

Fishbowl is an ideal solution for small to midsize businesses, particularly those in the manufacturing and distribution sectors. Key features include:

Order management

With Fishbowl, you can streamline your order processes, right from the initial customer inquiry through to delivery, ensuring timely and efficient order fulfillment.

Manufacturing

Fishbowl’s features allow you to easily create complex manufacturing orders and monitor the production process, helping you maintain optimal production levels.

Asset tracking

Keep track of your assets with Fishbowl’s advanced barcode and tracking tools, ensuring you always know where and how they’re being used.

Oracle NetSuite

Oracle NetSuite WMS is a robust solution for small and large businesses. Key features include:

Inbound/outbound logistics

Oracle NetSuite enhances your supply chain performance with efficient shipping and receiving processes, enabling faster turnaround times and improved customer satisfaction.

Inventory visibility

With Oracle NetSuite, you gain real-time visibility into your inventory across multiple locations, helping you to maintain optimal stock levels and avoid stockouts or overstocks.

Advanced fulfillment

Oracle NetSuite’s advanced wave planning, picking, and packing capabilities make order fulfillment a breeze, reducing the time it takes to get products out the door and into your customers’ hands.

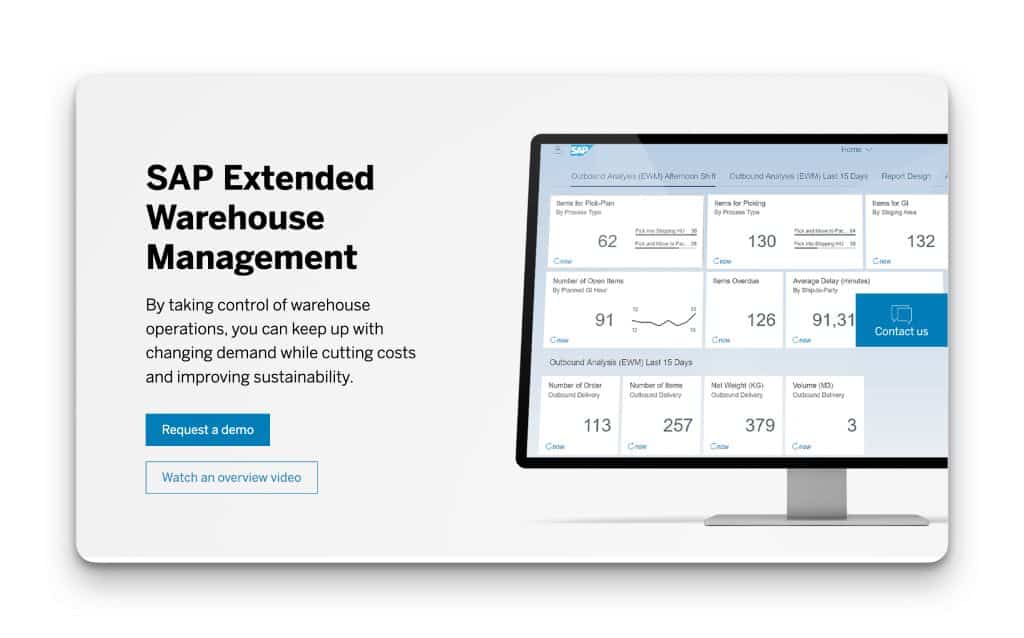

SAP Extended Warehouse Management

SAP EWM is suitable for midsize to large enterprises, particularly those with complex warehousing needs. Key features include:

Advanced picking and packing

SAP EWM uses advanced techniques for picking and packing goods efficiently, reducing time and errors in the order fulfillment process.

Slotting and rearrangement

With SAP EWM, you can organize your warehouse layout for maximum efficiency, improving the use of space and reducing the time it takes for workers to move around the warehouse.

Labor management

SAP EWM allows you to plan and monitor labor resources effectively, ensuring that you always have the right people in the right place at the right time.

Infor WMS

Infor WMS is a highly configurable platform ideal for businesses with complex supply chains and warehouse operations. Some of its key features include:

3D visual warehouse

Infor WMS offers a unique 3D visual interface that lets you understand your warehouse layout in real-time, improving efficiency and accuracy in picking and placement processes.

Labor management

With Infor’s advanced labor management tools, you can track performance, plan workload and align resources effectively, leading to improved workforce productivity.

Cross-docking

Infor WMS enables efficient cross-docking, which reduces storage and labor costs by directly transferring inbound goods to outbound gates.

Manhattan SCALE

Manhattan SCALE is designed for mid-market companies looking for a holistic solution that fits complex distribution needs. It includes the following features:

Multi-carrier shipping

With Manhattan SCALE, you can optimize shipment schedules and select the best carrier for each shipment, leading to cost savings and improved delivery times.

Order lifecycle management

This feature efficiently manages the entire order process from procurement to delivery, ensuring customer satisfaction and repeat business.

Labor management

By monitoring and measuring worker performance, Manhattan SCALE helps to allocate labor resources where they are needed most, leading to increased efficiency and lower operational costs.

3PL Warehouse Manager by Extensis

3PL Warehouse Manager by Extensis is designed for third-party logistics companies and warehouses, helping them to manage multiple clients and large volumes of orders.

Key features include:

Client billing

The software automates your billing processes, freeing up your time to focus on more critical tasks.

Customer portal

With a dedicated customer portal, your clients can place orders, track inventory and generate reports, fostering a more transparent and interactive customer experience.

SmartParcel

This feature allows for seamless integration with various carriers and eCommerce platforms, ensuring faster and more accurate shipping.

Blue Yonder

Blue Yonder is a warehouse management solution suitable for industries like retail, manufacturing, and logistics services. It is designed to optimize and orchestrate complex warehouse operations. Key features include:

Luminate warehouse tasking

Leveraging machine learning, this feature optimizes resources and tasks in real-time, significantly boosting productivity and reducing costs.

Warehouse labor management

Blue Yonder’s solution monitors labor performance and provides insights for improvement, leading to greater workforce productivity and operational efficiency.

IoT enabled

By integrating IoT devices, Blue Yonder enables real-time inventory and equipment tracking, facilitating more precise and timely decisions.

Körber

Körber’s warehouse management software is designed to handle the most complex supply chains and warehouse operations. It offers a suite of functionalities including:

Seamless Integration

Körber’s WMS can be integrated with a wide range of systems such as ERP, TMS, and automation systems, ensuring smooth and cohesive operations across your entire supply chain.

Advanced Analytics

With its powerful analytics capabilities, Körber allows you to extract insights from your warehouse data and make informed decisions that enhance your operations.

Personalized User Interface

The user interface can be personalized to match the needs of individual users, improving user experience and productivity.

Magaya WMS

Magaya WMS is well-suited for businesses that deal with heavy cargo and need to manage warehouse operations efficiently. The platform offers the following features:

Complete cargo control

From receiving to shipping, Magaya WMS provides complete control and visibility over your cargo, reducing errors and improving efficiency.

Cargo dimensioning

The software allows you to capture cargo dimensions automatically, facilitating better space utilization in your warehouse.

Mobile App

With the Magaya WMS mobile app, you can manage your warehouse operations from anywhere, anytime, ensuring uninterrupted productivity.

Epicor

Epicor WMS is designed to meet today’s complex warehousing needs, making it a preferred choice for manufacturers and distributors. It provides features such as:

Comprehensive inventory control

Epicor provides a detailed view of inventory in real-time, helping businesses streamline operations, reduce errors, and increase efficiency.

Advanced material handling

The software offers comprehensive material handling capabilities, including order routing and task interleaving, to maximize warehouse space and operational efficiency.

Warehouse analytics

Epicor provides in-depth analytics and reporting tools to help warehouse managers make data-driven decisions and improve overall warehouse performance.

Zoho Inventory

Zoho Inventory is an excellent option for small to midsize businesses looking to optimize their inventory and order management. It offers a range of features including:

Multichannel selling

Zoho Inventory supports multichannel selling, synchronizing inventory across all your sales channels in real-time to avoid overselling and stockouts.

Order management

The software provides comprehensive order management features, allowing businesses to fulfill orders faster and more accurately.

Warehouse management

With Zoho Inventory, you can manage multiple warehouses, transfer stock between warehouses, and get detailed reports on warehouse operations.

ShipHero

ShipHero is specifically tailored for eCommerce businesses, offering comprehensive solutions to streamline warehouse operations and improve fulfillment efficiency. Key features include:

Automated shipping

ShipHero automates your shipping processes, significantly reducing manual work and helping to get orders out the door faster.

Batch picking

This feature allows for the grouping of similar orders into a single batch, improving picking efficiency and accuracy.

Detailed reporting

ShipHero provides comprehensive reporting and analytics tools, offering actionable insights to optimize your warehouse operations.

Peoplevox WMS

Peoplevox WMS is a mobile-first warehouse management solution that empowers eCommerce businesses to deliver exceptional customer service. Its key features include:

Real-time inventory management

Peoplevox WMS provides real-time inventory visibility, helping you prevent stockouts and overstocks and improve order accuracy.

Flexible warehousing

The software allows for creating custom warehouse layouts, zones, and bin locations, enabling you to optimize your warehouse space and improve picking routes.

Easy-to-use interface

With an intuitive, easy-to-use interface, Peoplevox WMS ensures your team can quickly get up to speed and work efficiently.

Logiwa

Logiwa is designed for high-volume eCommerce and wholesale businesses, offering comprehensive warehouse and inventory management solutions. Notable features include:

Warehouse process automation

Logiwa’s automation capabilities increase productivity by reducing manual tasks, helping businesses ship orders faster and more accurately.

Integrated shipping and labeling

With integrated shipping and labeling, Logiwa simplifies fulfillment processes and ensures that orders are delivered correctly and on time.

Real-time inventory tracking

Logiwa provides real-time inventory tracking across multiple locations, reducing stock discrepancies and enabling more effective inventory control.

Implementing warehouse optimization software

Introducing a new warehouse optimization software is not an overnight task. It requires meticulous planning, execution, and commitment.

While software providers offer implementation support, understanding the process can be beneficial to maximize the value of your investment.

Planning and evaluation

The first step in the implementation process is assessing your warehouse needs. This involves a deep dive into your existing operations to identify pain points and areas for improvement.

The results of this analysis help in configuring the software to meet your specific business needs.

Data migration

Once your warehouse processes are evaluated, the next step involves data migration. This can be complex, especially if moving from a manual system or another software platform.

The new system should include all necessary product details, stock levels, supplier information, and customer data.

System configuration and customization

After the data is migrated, the software is configured and customized based on your operational needs.

This could involve setting up rules for picking, packing, and shipping and establishing warehouse layouts within the system.

User training and adoption

User training is perhaps the most critical aspect of software implementation. Effective training ensures all users are comfortable with and can fully utilize the system.

The more user-friendly the system, the smoother the adoption process will be.

Evaluation and continuous improvement

Once the software is up and running, it’s important to evaluate its performance regularly. Collect user feedback, monitor key performance indicators (KPIs), and work with the software provider to implement any necessary changes or improvements.

Achieve Peak Efficiency with SkuVault Core

In a market saturated with options, SkuVault Core’s warehouse optimization software stands head and shoulders above the competition

Built with a focus on solving real-world problems, it delivers on all fronts, making it an indispensable tool for any warehouse operation. SkuVault Core offers robust functionality, including complete inventory visibility, quality control, and detailed reporting, among others. Its easy-to-use interface and reliable customer support ensure you’re never left in the dark. We designed the software with scalability in mind, ensuring that as your business grows, SkuVault Core grows with you.

Investing in SkuVault Core is not just about buying a software solution; it’s about partnering with a team committed to your success. With continuous updates and improvements based on user feedback, you’re guaranteed a system that remains at the forefront of warehouse optimization technology.

Ready to see SkuVault Core in action? We’ve created an interactive product tour that lets you dive into the platform and see how it all works. No sales reps, no sales pitch. And it takes just 3 minutes. Take the tour now.

FAQs about warehouse management software

Navigating the world of warehouse management software can be complex, especially with the range of options and technical jargon. Here are some commonly asked questions to help clarify some points:

What’s the difference between inventory management software and warehouse management software?

Inventory management software focuses on tracking goods and materials throughout your supply chain, from procurement to sales. It’s all about knowing what you have and where it’s located.

On the other hand, warehouse management software dives deeper into the daily operations within a warehouse. It helps manage picking, packing, shipping, and storage processes. Both types of software often integrate with each other for a comprehensive warehouse solution.

What are some best practices for distribution center management?

Effective distribution center management requires a mix of efficient processes, advanced technology, and skilled employees. Some best practices include:

- Regularly reviewing and optimizing warehouse layout to minimize movement time.

- Implementing a warehouse management system to automate processes and improve accuracy.

- Offering regular training to staff to ensure they are up-to-date with the latest processes and technology.

- Using data and analytics for informed decision-making and continuous improvement.

Is warehouse management software suitable for small businesses?

Absolutely. Many warehouse management solutions are scalable, making them suitable for businesses of all sizes.

For smaller operations, they can simplify processes, improve accuracy, and ultimately save both time and money. As the business grows, the software can scale to accommodate increased demand.

How can I choose the right warehouse management software for my business?

Choosing the right warehouse management software involves understanding your business needs and evaluating how different solutions can meet these needs.

Consider factors like budget, the software’s features, its ability to integrate with your existing systems, and the level of customer support provided. Also, look for user-friendly software that your team can easily adopt.

What is the ROI of implementing a warehouse management system?

The return on investment (ROI) from implementing a warehouse management system can be significant. These systems can lead to cost savings from increased efficiency, reduced errors, and better space utilization.

Additionally, they can help increase sales by improving order accuracy and customer satisfaction. The exact ROI will depend on various factors, including the size of the operation and the specific challenges the software helps address.